About this deal

With these factors in mind, what constitutes a thorough sump flush? Are there any particular problems that the operator should be careful to avoid? What equipment can or should be used for this purpose? Finally, what items should be included in a detailed flushing procedure? If it did its job, your engine’s performance will return to the heady days of its youth, when it delivered maximum power and efficiency. Regardless of the flushing compound/fluid selected, unless it is identical to the lubricant used following the flush, it is important that all of the flushing fluid be removed from the sump prior to final fill. Some petroleum solvents with a concentration of five percent can create an appreciable thinning effect on the lubricant viscosity. Because flushing is designed as a part of the lifelong maintenance program, preparations for such should be included in the design phase. This seldom occurs, for it is not common to design special flushing connection ports, top and bottom air-bleed ports, premounted by-pass loops, etc. in the system. In addition, sufficient requirements for subcontractors regarding procedures and documentation for flushing subsystems are needed.

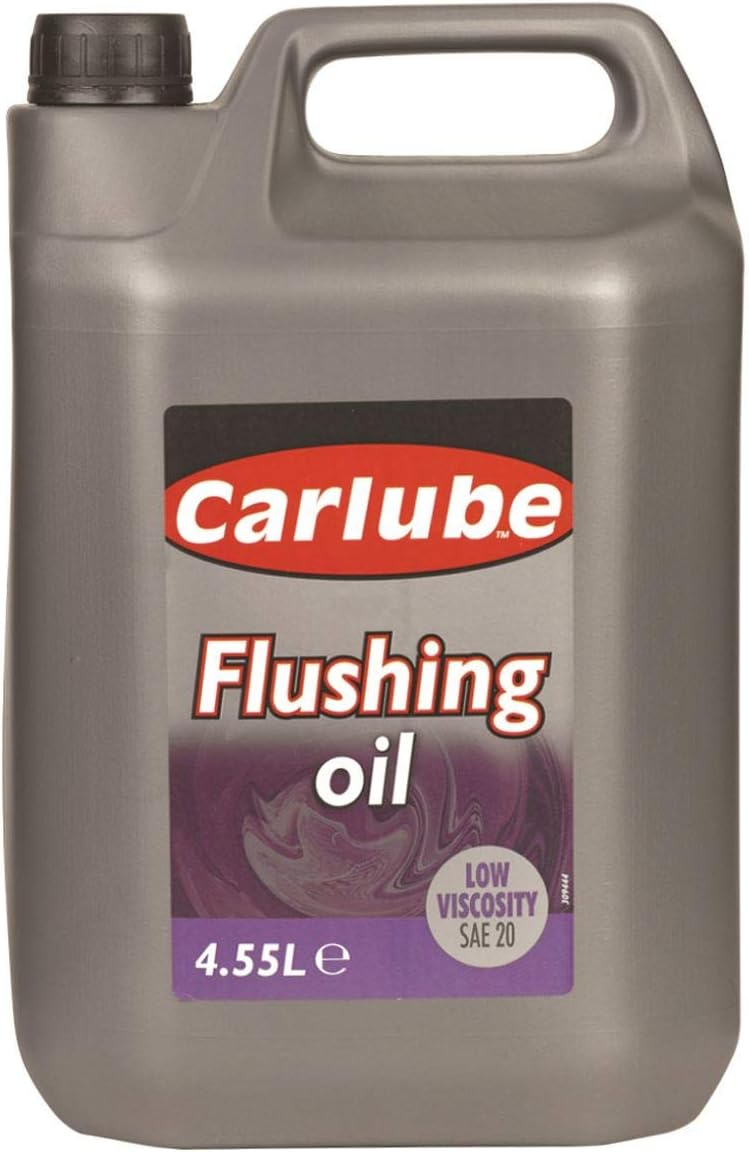

Engine Flushing Oil - Rye Oil Limited

Flushing your engine helps ensure it manages heat properly for optimum efficiency and oil life. 5. Convenience Chemical cleaning– The use of chemicals that can dissolve inorganic components. Chemical cleaning may incorporate the use of aqueous alkali or acid solutions to accomplish the desired result. Flushing after modifications and/or updates.Handle this the same way as for newly fabricated systems.Precision steel tubes - cut, graded and free from scale and corrosion - should be subjected only to chemical cleaning and hot oil flushing. Welded tubes should be mechanically cleaned inside by a plastic pig. A pig, also referred to as a go-devil or rabbit, is a plug with brushes, scrapers and rollers on its periphery. It moves under the oil pressure through a pipeline and cleans it. This ensures the tubes and tube flanges are smooth and free from slag, welding beads (spatter) and foreign particles. After six hours of operation, shut down the system, replace the filters and sample and test the fluid. Data dirimu akan digunakan untuk verifikasi akun ketika kamu membutuhkan bantuan atau ketika ditemukan For new or rebuilt machines to remove contamination resulting from manufacture, service or overhaul. The fluid system can be contaminated due to dirty assembling elements, corroded surfaces, water, oxidation products and incompatible elastomers such as seals, sealants and coatings. Also, during the assembly process, dirt is ingested and debris is generated due to threading, joining, welding, etc.

What Is an Oil Flush? Are They Necessary? - NAPA Know How Blog

However, brake cleaner includes a number of chemicals such as acetone and tetrachloroethylene. These solvents are known to cause problems for nitrile, neoprene, millable polyurethane and silicone seals. Ethylene-propylene (EPDM) seals have a very poor petroleum oil and solvent resistance, and are not recommended for exposure to aromatic hydrocarbons or diesel oil. Tom Odden. “ Cleaning and Flushing Basics for Hydraulic Systems and Similar Machines.” - Machinery Lubrication magazine, July 2001. Poor decision-making and not having the right people involved can delay an oil flush longer than any of the items listed above. Identifying the decision-maker for all parties on the front end can eliminate many delays. More than 90 percent of oil flushing today runs 24 hours a day and seven days a week, so having decision-makers available at the right time can save days with some oil flushes. In some cases, it is more cost-efficient to perform periodic cleaning (such as a proactive flushing) instead of a costly upgrade or a complete modification of the system. Note that it is often possible to perform a flush while system is in operation. Yes, but that was a long time ago, the same month that i got the car. Since then I got rid of the metalic filter located on the banjo bolt and after the engine flush, did around 20k km and 2 oil chages in that interval befor my first ever problems with the turbo

About Carlube

Risks – if an insufficiently amount of solubility enhancer is used or the residence time is too short then it can be rendered less effective. Tesco Mobile is to start charging new and recently joining pay-monthly customers to use their mobiles in Europe from 2024. Do you need to change the gearbox oil? I thought modern cars do not need this doing. I've never changed gearbox oil in any car and never had a gearbox problem.

ENGINE FLUSHING. IS IT EVEN WORTH IT AND IF YES - Castrol

Turbo boost your credit chances and get your free Experian credit report. Credit Card & Loans Eligibility Calculator This is why the final flushing of complex systems often becomes a challenge for management because of increasing costs and delayed completion and recommissioning. Shortcuts often become an easy and sometimes preferred choice. Although such shortcuts can postpone problems, they don’t always solve them. You pour it into your engine’s oil-filler port and idle the engine for about 10-15 minutes. It mixes with the oil and circulates through the engine, helping dissolve sludge and clean deposits. The fluid velocity (V) should not be less than 2 to 3 m/sec. (106 ft./sec.) in any part of the flushing loop. This prevents settling of particles inside tubes and hoses. Use the Wynn's Engine Flush Petrol and Diesel 425ml prior to an oil change to get rid of sludge and other contaminates from the vital engine parts with ease. Ideal for use with all petrol and diesel engines of vehicles and stationary equipment.

Flushing Strategies for Systems In-service

Yes. The transmission oil loses viscosity and breaks down over time, significantly decreasing the ability to prevent wear. Plus you have all those metal bits floating in your transmission doing further damage.

Flushing Basics for Hydraulic Systems and Cleaning and Flushing Basics for Hydraulic Systems and

It is important to include verification routines each time a subsystem is connected to the main system. Providing for these specific recommendations in the overall plan builds confidence and eliminates costly rework at the end of the project.High Flush Oil Temperature—This reduces viscosity, increases turbulence and increases oil solvency. Temperatures in the range of 175 to 195 degrees F are generally targeted. I think you have to accept that with that history of neglect it does not haven a long prospect in front of it. However, if it were mine I would not be able to bear running it knowing all that dirt was inside, so I think it would be a rare instance where a flush would be the least bad option. A lot of people are simply draining the box and filling it with new oil. Now I'm sure just draining and filling it will get rid of most of the crap. But having observed kitchen sinks many times I know that the heavier deposits don't actually drain away completely, they're too heavy and just sit at the bottom and don't budge. I'm qworried that if I just drain and reful, the bigger bits of metal will remain inside. The flushing procedure depends on the specifics of machinery, plant conditions and flushing equipment. To obtain the best results, follow these guidelines:

Great Deal

Great Deal